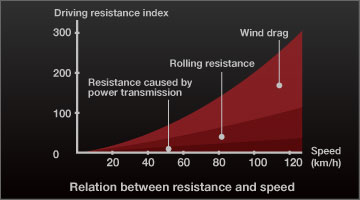

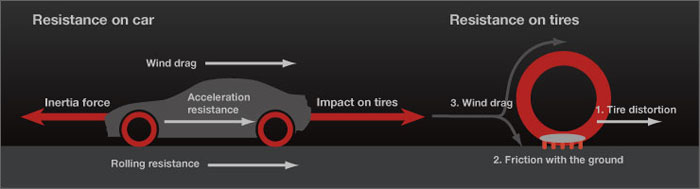

Rolling resistance refers to the various forms of resistance against driving force when the car is in motion. Several factors contribute to rolling resistance, including wind drag on the car, acceleration resistance generated by inertia force when speeding up, and resistance on the tyres.

As a tyre flexes when it rotates, friction between molecules causes energy to be converted to heat. This is known as hysteresis loss. Such loss accounts for the majority of all rolling resistance in a tyre (approximately 90%). Rolling resistance is lower in radial tyres than bias tyres, and decreases with low-aspect tyres that have high tread rigidity.

When force is applied to rubber (viscoelastic body), energy is converted to heat and then lost as the shape changes. For that reason, it is imperative to keep air pressure at an appropriate level to suppress unnecessary distortion and minimize energy loss.

Although differing by road surface condition, tyre type and tread pattern, resistance caused by friction between the tyre and the ground accounts for less than 10% of total rolling resistance.

Resistance is extremely minimal at low speeds and can be ignored.