Free Inquiry

We welcome your comments, requests and questions, regarding Yokohama tires sold in Qatar.

Address

Yokohama Salwa Showroom & Service Centre

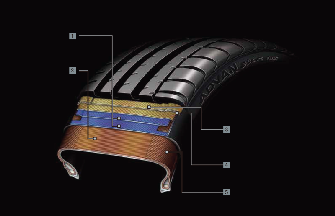

1) High rigid steel belts

Steel belts prevent the carcass from turning up at high speeds and improve stability.

2) Rayon carcass

The high-spec rayon within the tyre body meets the demands of European car manufacturers for original equipment tyres.

3) Overlapped jointless winding system

Overlapping the belt covers the edges and enhances durability.

4) Jointless triple-edge cover

Both edges are folded up to create a high-rigidity, jointless belt cover.

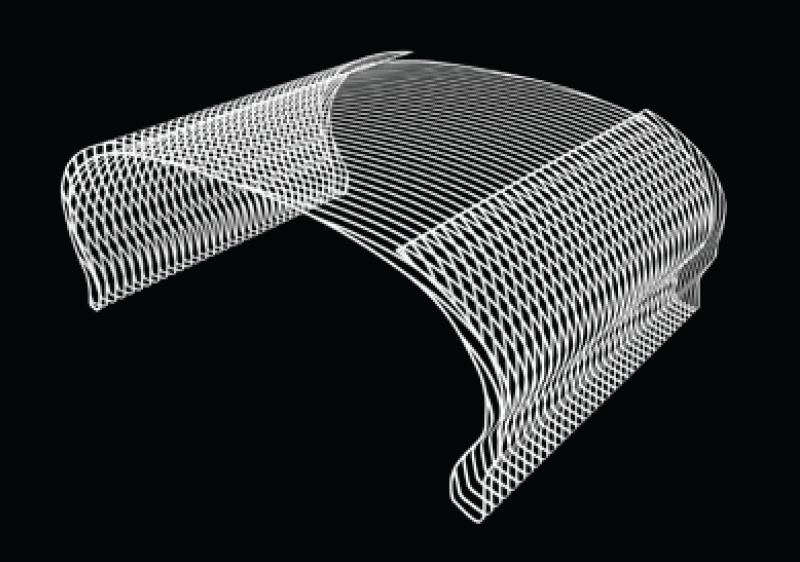

5) Matrix body-ply

The new structure offers improved circumferential rigidity for optimum steering stability.

The angled ply is close to the tread. Circumferential rigidity is improved through a double structure spanning the cover from sidewall to shoulder, enhancing steering precision without diminshing ride comfort. It also improves dry grip by maintaining contact with the road surface.

Matrix Body-Ply: The high side rigidity allows the tread and bead to roll without deviation, yielding quick and accurate steering response.

Conventional Construction: If side rigidity is low, the tyre becomes distorted, delaying the reaction between the tread and the bead, and reducing steering precision.

To achieve a powerful grip, designers optimized and enlarged the contact patch and added large blocks and large grooves. To further improve wet surface performance, the main groove stays at the centreline of the contact patch when turning. That layout exhibits superior water shedding characteristics when cornerning.

1) Variable width circumferential grooves

Uses wider 3+1 main grooves.

Displays exceptional hydroplaning resistance at high speeds.

2) High-rigidity wide shoulder

Significantly improved pattern rigidity at ultrahigh speeds and realizes powerful grip on dry surfaces.

3) Silent Sipe

These thin slits positioned on the inboard of the ribs suppress external vehicle noises.

Asymmetric Pitch Variation

Optimized pitch on the inboard and outboard side of the tyre to enhance both manoeuvrability and quietness.

The compound for V105 tyres was developed with the cooperation of a leading European car manufacturer, and the objective was to achieve a very high level of performance. At the beginning, the staff was given the objective of "making the best rubber in the world". They did simulations that mixed and balanced many ingredients, looking fo the ideal mixture. The new compound developed shows gripping power never achieved before.

| Inch | Size | Art. | Aspect Ratio | Load Index | Speed Symbol | Origin |

|---|---|---|---|---|---|---|

| 16 | 205/55R16 91VV105 W L BZI7 | F4923 | 55 | 91 | V | JPN |

| 18 | 235/60R18 A3VV105 W L BZC3 | F7498 | 60 | 107 | W | JPN |

| 18 | 255/40R18 95YV105 WRBL BZI7 | F5076 | 40 | 95 | Y | JPN |

| 18 | 255/40R18 99YV105 WRBL BZI7 | F4288 | 40 | 99 | Y | JPN |

| 18 | 285/35R18 97YV105 WRBL C3BZ | F5331 | 35 | 97 | Y | JPN |

| 18 | 285/35R18 97YV105 WRBL BZC3 | F4289 | 35 | 97 | Y | JPN |

| 19 | 235/40ZR1992YV105 WRBL POCC | F7766 | 40 | 92 | Y | JPN |

| 19 | 235/55R19 A1VV105 W L BZC3 | F7499 | 55 | 101 | Y | JPN |

| 19 | 245/40ZR1998YV105 WRBL BZC3 | R0713 | 40 | 98 | Y | JPN |

| 19 | 275/35ZR19A0YV105 WRBL BZ | R0714 | 35 | 100 | Y | JPN |

| 19 | 275/40ZR19A5YV105 WRBL BM | R3343 | 40 | 105 | Y | JPN |

| 20 | 245/35ZR2095YV105 WRBL BZ | R0715 | 35 | 95 | Y | JPN |

| 20 | 255/30ZR2092YV105 WRBL AUI7 | F8458 | 30 | 92 | Y | JPN |

| 20 | 255/40ZR20A1YV105 WRBL POI7 | F5395 | 40 | 101 | Y | JPN |

| 20 | 275/30ZR2097YV105 WRBL BZ | R0716 | 30 | 97 | Y | JPN |

| 22 | 285/35ZR22A6YV105 WRBL PORY | R5600 | 35 | 106 | Y | JPN |

| EU LABEL GRADE | ||

| Fuel Efficiency | 1 - 3 | |

| Wet Grip | A - C | |

| External Noise Class External Noise Value (dB) |

1 - 3 69 - 75 |

|